Application Background of the Park´s Full-Perception UAV and Robot Dog Patrol System

With the continuous expansion of the scale and the increasing complexity of functions of parks (including industrial parks, logistics parks, chemical parks, etc.), the traditional manual inspection mode can no longer meet the needs of modern park safety management and control, environmental monitoring, and efficient operation and maintenance. There is an urgent need for more intelligent and comprehensive inspection solutions, and thus the park´s full-perception UAV and robot dog patrol system has emerged. Previously, manual inspection had many obvious shortcomings: first, the coverage range is limited. For special scenarios in the park such as tall installations, narrow pipeline corridors, and large-area storage areas, it is difficult for manual workers to reach or conduct a comprehensive inspection, which easily forms inspection blind spots; second, the efficiency is low. Manual inspection consumes a lot of time and manpower, and is affected by the physical strength, experience of personnel and weather conditions. It is difficult to achieve 24-hour uninterrupted inspection, and it is impossible to detect sudden hidden dangers in a timely manner; third, the data collection is single. Manual inspection mostly relies on paper records or simple equipment photography, making it difficult to simultaneously obtain multi-dimensional data such as environmental parameters (e.g., harmful gas concentration, temperature, humidity) and equipment operation status. Moreover, data collation and analysis are lagging, which cannot provide real-time support for park management decisions.

Hardware Equipment

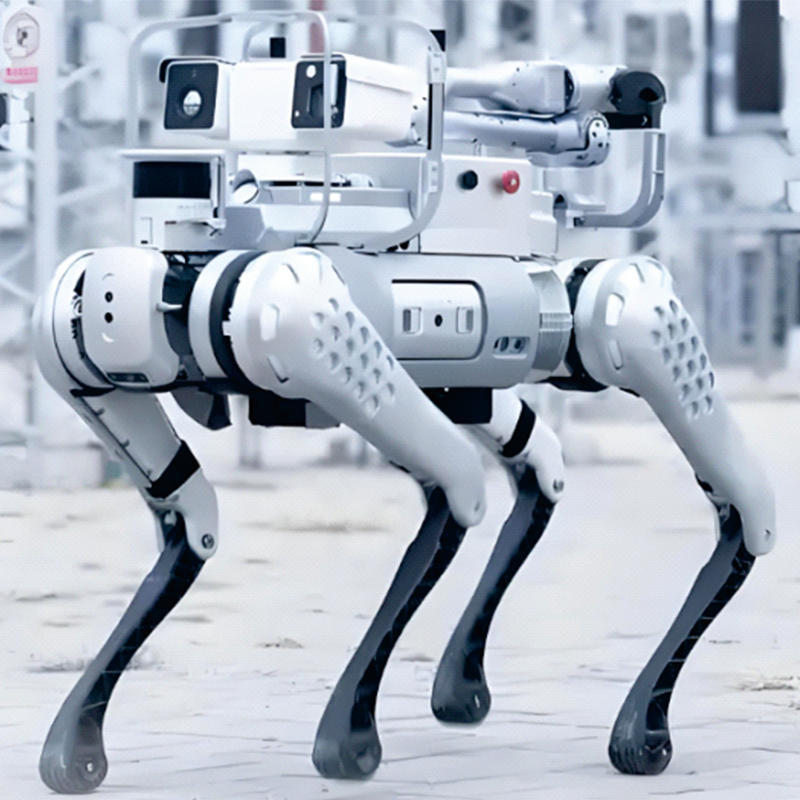

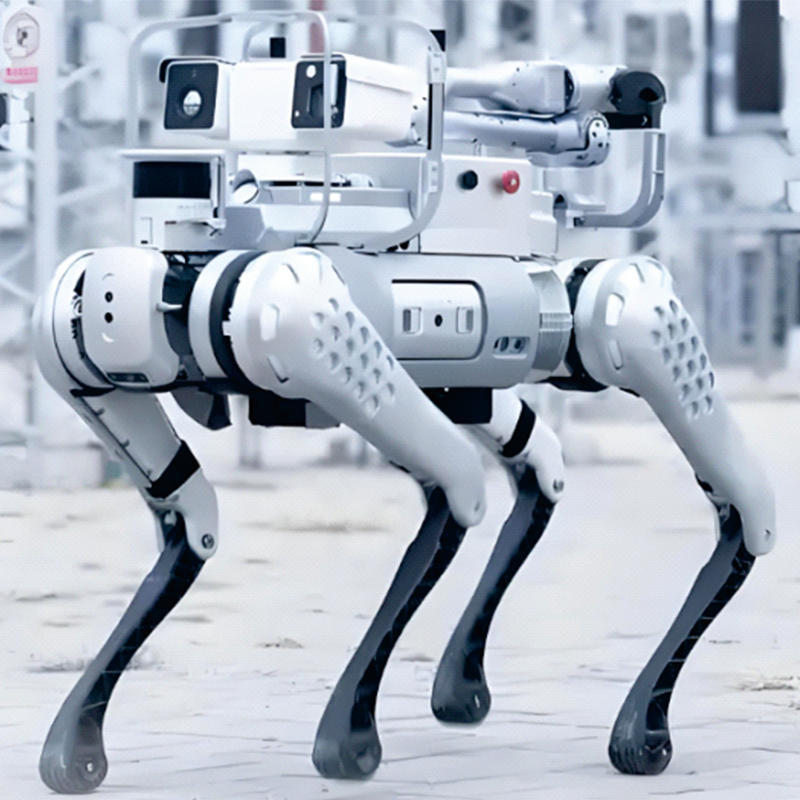

Robot Dog Full-Perception Patrol System

System Overview

In the industrial park scenario, relying on its excellent flexibility and mobility, the robot dog can move and shuttle quickly inside the park. It can flexibly perform various movements such as walking, running, and crawling. Even when facing narrow passages, equipment gaps with varying heights, or rough and complex terrain, it can easily pass through and reach areas that are difficult to access during manual inspection due to space limitations and terrain obstacles, effectively filling the coverage blind spots of traditional inspections.

At the same time, the robot dog is equipped with high-precision monitoring sensors and an AI intelligent recognition module. During the inspection process, it can conduct real-time monitoring of the operation status of mechanical equipment in the park, accurately capture potential faults such as abnormal vibration and abnormal temperature of the equipment, and feed back in a timely manner. In addition, it can also collect and analyze the gas concentration in the spatial environment of the inspection area in real time, and accurately locate possible leakage points of pipelines through AI recognition technology, detecting risks such as excessive pollutant discharge and gas leakage at the first time, which significantly improves the detection accuracy and overall operation efficiency of inspection work in industrial parks.

System Functions

Air Quality Monitoring: Conduct real-time dynamic monitoring of the air quality in the industrial park. The monitoring scope covers the concentration changes of various pollutants such as sulfur dioxide, nitrogen oxides, and various particulate matter (e.g., PM2.5, PM10), so as to fully grasp the air quality status of the park.

Emission Source Localization: With the help of high-definition camera equipment and multi-spectral cameras, it can clearly capture the pollutant discharge of enterprises in the park. Then, combined with the correlation analysis of pollutant concentration data obtained by the gas detection module, it can accurately locate the specific position of the pollutant emission source, providing a basis for traceability management and control.

Abnormal Alarm: When the system detects abnormal fluctuations in air quality (e.g., a sudden increase in pollutant concentration) or enterprise emissions exceeding the standard limits, it will immediately trigger an early warning mechanism, push the early warning information to the management personnel´s terminal equipment (e.g., mobile phones, computers), and simultaneously mark the specific location where the abnormal situation occurs to facilitate rapid response.

Data Analysis and Report Generation: It can automatically collect various data generated during the inspection process, sort and classify the data, and generate a structured air quality report. The report supports export in common formats such as PDF or Excel, which is convenient for management personnel to file, analyze, or report to higher-level departments.

Keyword: