Background of acoustic imaging equipment for automobile manufacturers

Automakers use acoustic imagers mainly to improve the accuracy and efficiency of automotive quality inspection. These advanced devices utilize sound wave technology to monitor the interior of cars in real-time, effectively capturing and analyzing the noise and vibration generated by the vehicle during operation. Through imaging analysis of sound waves, acoustic imagers can help engineers identify potential defects in automotive design or manufacturing, such as loose components, uneven materials, or welding quality issues.

This technology can not only detect potential problems in a timely manner during the production stage, prevent unqualified products from entering the market, but also provide valuable data support in vehicle maintenance and repair processes, thereby improving the comfort and safety of automobiles. In summary, the application of acoustic imaging devices enables automobile manufacturers to more accurately control production quality, improve overall vehicle performance, and enhance user experience.

Introduction to Acoustic Imaging Devices for Automobile Manufacturers

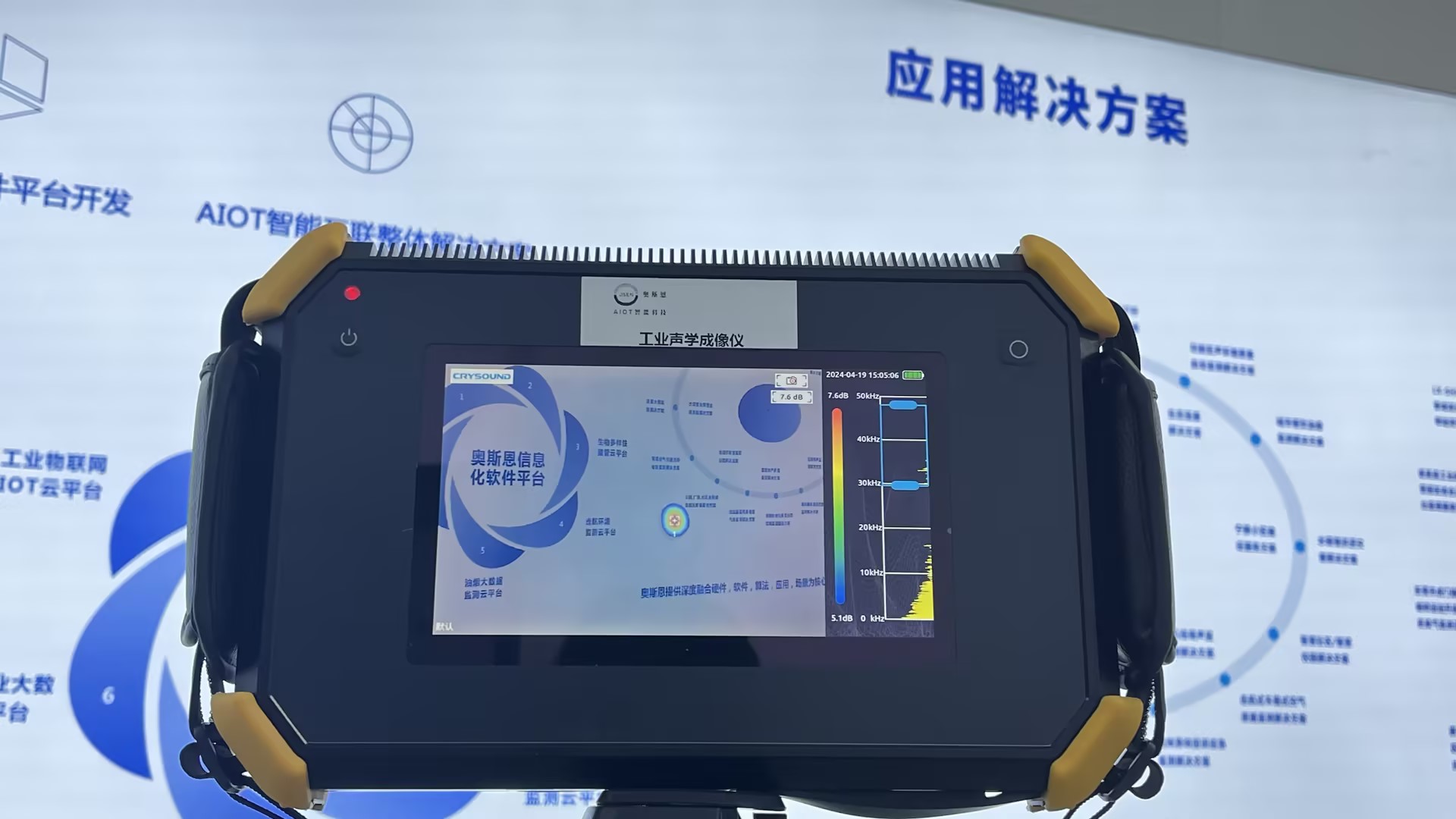

Handheld acoustic imaging device

The handheld acoustic imaging device supports both audible and ultrasonic frequency band imaging. The instrument uses microphone array technology to collect audio data and cooperates with high-definition cameras to capture real-time images. After analyzing the array audio data using beamforming sound source localization technology, the sound source and distribution data are obtained. Then, the sound source distribution data is fused with the video image to generate a sound image cloud map, and finally the sound source dynamics are presented on the display screen. In power system operation and maintenance, it can help you quickly and accurately detect partial discharge and identify the type of partial discharge.

Main interface display

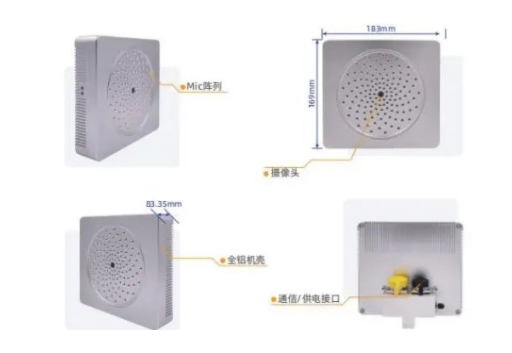

Modular acoustic imaging device

The acoustic imaging module is developed in conjunction with application scenarios such as power system inspection robots, drones, and online monitoring. It is compact in size, easy to install, supports wired data transmission, and can expand WI-FI transmission. The test data currently supports streaming transmission through RTSP/RTMP.

Equipment features

-Up to 128 MEMS Mic ultra long distance and testing accuracy

-IP56 protection level meets outdoor monitoring usage scenarios

-183mmX 169mmX 85.35mm Small size for easy installation

-Ultra wide range of 2KHz-48KHz

-The bottom comes with M5 thread and 1/4-20UNC thread for easy fixation of the gimbal

-All aluminum casing is safe and reliable

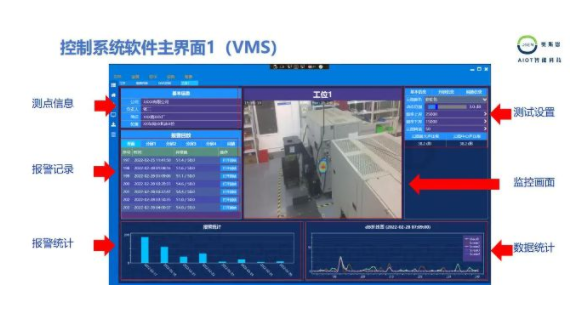

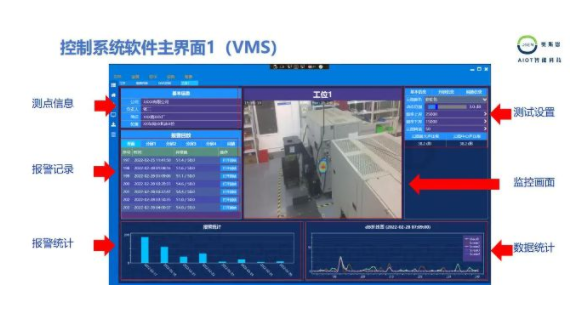

Intelligent Inspection System

The acoustic imaging module is combined with inspection robots, drones, and inspection vehicles to achieve efficient, automatic, and intelligent inspection. Fault information is transmitted in real-time to the control center for real-time fault analysis and alarm, truly achieving intelligent inspection.

application area

1. Chemical industry (including petrochemical, refining, and coalification): key positions of pressurized gas pipelines/valves, tanks, and kettles/furnaces.

2. Oil and gas transmission/purification: Leakage monitoring of natural gas transmission pipelines/gas gathering/purification treatment stations.

3. Steel and metallurgy: special toxic gas pipeline/flange leakage monitoring, tail gas combustion furnace gas leakage monitoring.

4. Manufacturing industry: Power compressed air leakage monitoring/online automatic monitoring of tank leakage.

Keyword: