OSEN 3001S TYPEPORTABLE LASER DUST PARTICLE COUNTER

The OSEN 3001S 2.83L min portable laser particle counter is a compact device for cleanliness measurement in clean environments. Designed for precision testing and quantification of cleanroom air quality, it features a color LCD touchscreen with a sleek design, lightweight construction, high precision detection, and intuitive operation. Equipped with computer control, the instrument stores and prints sampling results, making environmental monitoring effortless. Widely used in pharmaceutical plants, electronics factories, hospital operating rooms, aerospace facilities, precision manufacturing, and food processing industries, this device delivers reliable performance, high measurement accuracy, an elegant appearance, and user friendly operation.

Product features

High precision sensor, accurate counting, excellent performance, in line with JJF1190 2008 specification requirements;

Integrated design, easy to install;

Equipped with 4.3 inch smart touch screen, real-time display and monitoring data;

Internal vacuum source, small vibration, low noise and stable performance;

You can directly set the instrument address on the screen, which is convenient for field replacement;

Screen data alarm, real time monitoring of traffic and real-time self adjustment of traffic;

Using 28.3L large flow sampling, the sampling accuracy and efficiency are greatly improved;

Long life imported semiconductor laser source, life more than 30,000 hours annual calibration is required;

RS485 communication, support ModbusRTU protocol, support customized communication protocol;

Intelligent Internet of Things, can remotely start and stop, more accurate management of cleanliness level, improve the quality of cleanliness monitoring.

Product functions

Real-time measurement and display

It can accurately measure the number and particle size distribution of dust particles per unit volume in a clean environment, and display it digitally on the screen in real time.

Data storage and printing

Realize the setting of measurement parameters, display of measurement results, data storage and printing functions. The data memory can store multiple sets of measurement results for subsequent analysis and processing.

out of limit alarming

Supports the setting of different cleanliness levels. When the measurement result exceeds the set threshold, an alarm signal will be sent immediately to remind the user to take corresponding measures.

Remote control and management

It can not only carry out parameter setting, data query, data export and other operations remotely, but also comprehensively monitor the status of the instrument, grasp the running condition in real time, and find and deal with potential problems in time.

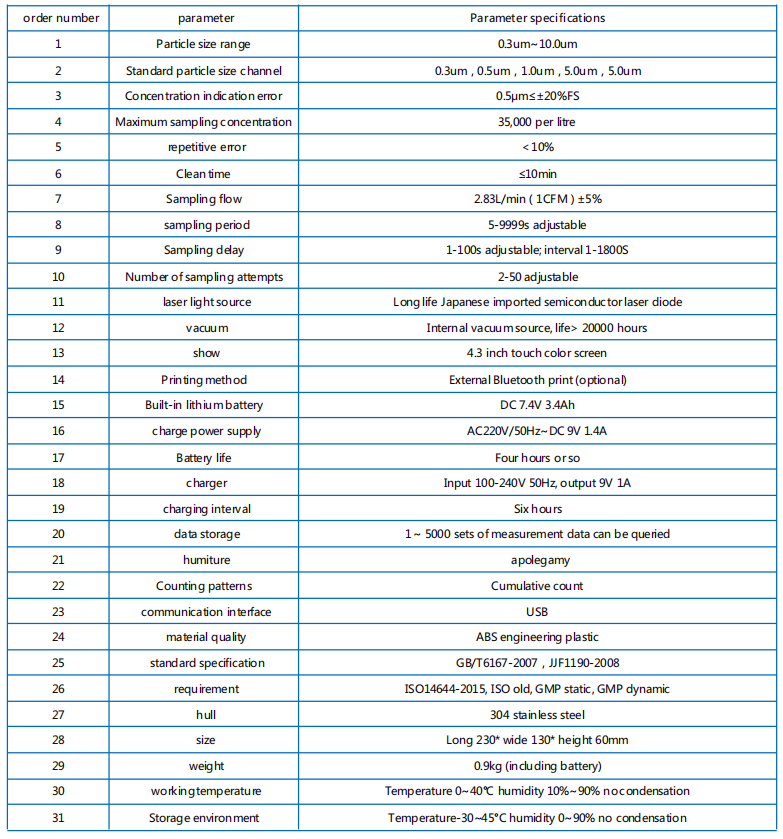

Product parameters